The Reliable Brake and Rotation Systems Built for Fire Trucks

🔥 When Seconds Matter, Reliability Isn’t Optional

In fire response, equipment failure isn’t just inconvenient—it can cost lives. That’s why fire truck manufacturers and upfitters choose components with precision, compactness, and long-term performance in mind. At the heart of many critical firefighting systems—like aerial ladders, platform rotations, and turrets—are Eskridge’s gear drive and braking solutions.

Built in the USA and backed by decades of field-proven performance, Eskridge’s Model 65, 105, and 130 rotation systems with integral brakes are the go-to choices for OEMs who demand safe, efficient, and compact motion control on every call.

🛠️ Compact Power for Complex Platforms: Meet the Models

Eskridge’s gearboxes aren’t just powerful—they’re space-conscious, efficient, and engineered for extreme duty. In fire truck design, every inch matters. And that’s where the integral brake assemblies make a real difference.

🔩 Model 65 Shaft Drive

- Compact yet robust for tight installation zones

- Lower backlash = smoother turret or ladder operation

- Integral brake for space-saving performance

🔩 Model 105 Shaft Drive

- Ideal for medium-load aerial platforms or rotary systems

- Backlash reduction reduces motion during ladder extension

- Designed for long-life performance, even in wet and rugged conditions

🔩 Model 130 Shaft Drive

- Suited for high-capacity platforms or demanding turret rotations

- Rugged design with field-proven braking systems

- Durable, even under dynamic loads

Each model delivers unmatched torque density and integrates a braking system within the gearbox—reducing both size and maintenance complexity compared to modular solutions.

🚨 Engineered for Emergency Response: Built for Pressure

In high-pressure environments like fire rescue, equipment must respond quickly, consistently, and safely. Eskridge products rise to the challenge with features designed for precision control and longevity.

✅ Low Backlash = Safer Ladder Control

Excess motion during ladder extension or rotation can destabilize operations at height. Eskridge’s Model 65 and 105 offer reduced backlash, translating into safer, more controlled deployment in high-angle scenarios.

✅ Rust-Resistant, Rain-Ready

Fire trucks operate in wet, dirty, and corrosive environments. Eskridge addresses this head-on with chemical plating options that defend against rust and corrosion—extending product life and performance reliability.

✅ Compact Design = More Room for Gear

With a built-in brake system, Eskridge gearboxes shorten the total drive length. That frees up space for auxiliary equipment, hoses, gear storage, or system wiring—helping OEMs optimize every square inch of the vehicle design.

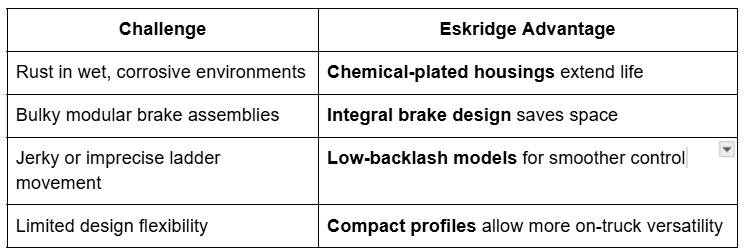

💡 Solving the Common Challenges in Fire Equipment Design

🏅 Quality That Commands Confidence

Choosing Eskridge means investing in a legacy of engineering excellence. Fire truck OEMs rely on Eskridge because they know our systems deliver low maintenance, high reliability, and seamless integration into even the most complex vehicle architectures. When failure is not an option, Eskridge stands as your silent, dependable partner behind the scenes.

📣 Ready to Equip the Front Lines?

Whether you’re a fire truck manufacturer, upfitter, or distributor, Eskridge offers mission-critical rotation and brake systems that meet the demands of real-world emergency response.

✅ Explore our full range of gear drives: Eskridge Gear Drives

✅ Reach out to our engineering team for a custom quote: Contact Us

📞 Need immediate support? Call us today and speak directly with an Eskridge expert.

Eskridge: Engineered to Break New Ground.

Compact. Reliable. Ready when it matters most.